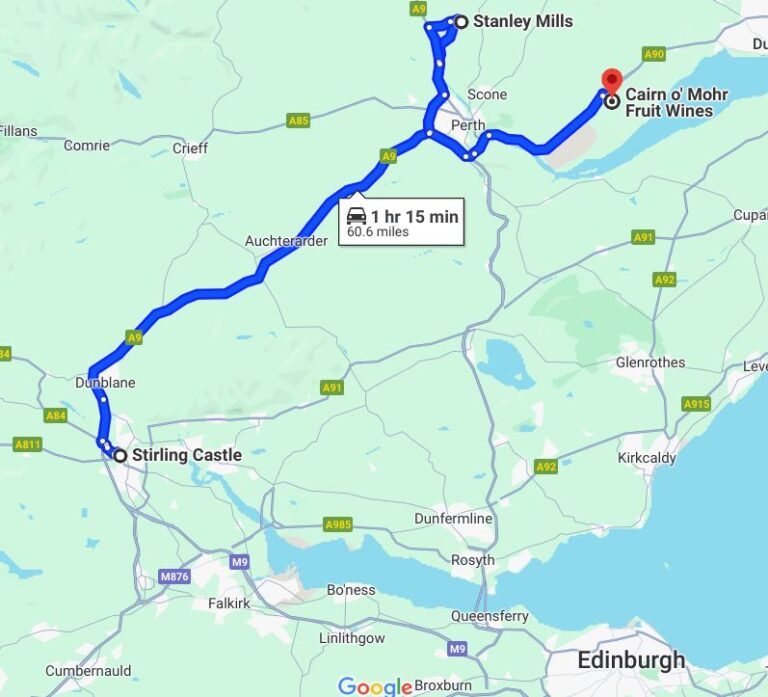

After leaving medieval Stirling we are heading north to see a prime example of the Industrial Revolution in England. Stanely Mills was first built in 1785 to spin cotton using water, diverted from the nearby Tay River, to drive waterwheels. Later, additional buildings and equipment were added to enable the mill to weave cotton and other fibres to produce a variety of products. The mill changed hands several times and was finally shut down in 1989.

Fire closed the mill twice and it also was closed from 1861-1865 due to the “Cotton Famine” caused by the American Civil War.

The nearby town of Stanley was purpose-built to house the workers and families for the mill. At its peak Stanley had a population of about 2000 people, with about 1000 of them working at the mill.

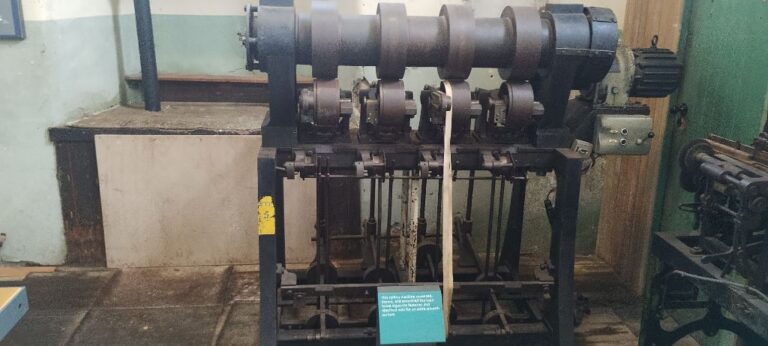

Prior to the introduction of machinery the step of cotton carding was done by hand. A very laborious and slow process. The industrial revolution introduced, amoung many other devices, the automated carding machine. Stanley Mills operated several of the machines that are used to turn raw wool into cotton slivers by aligning and combing the raw cotton fibres. Slivers are long, loose, roundish strips of cotton that are then fed into spinning machines to produce yarn.

In 1876 the owner of the mill introduced a new product “cotton belting”. This was sold around the world as belts to drive machinery. During the first and second world wars this belting was sold to the government as webbing for the armed forces.

A further refinement of belting, introduced in 1916, was “endless” thin cotton belting which was used in the product of cigarettes. This product helped Stanley Mills survived the Depression of the 1920s and 1930s.

Stanley Mills was an industry leader in innovation. One of these innovations was indoor toilets for workers. Not for the benefit of the workers, but to reduce time taken for toilet breaks and to allow the floor supervisors to better control the workers!

Women and children (under the age of 16) accounted for the majority of workers at Stanley Mills as they were paid less and were generally more available (children from orphanages were often a source of labour during the Industrial Revolution). Work hours were 5:30 am to 7:00 pm with two 45 minutes breaks at 9 am and 2 pm for meals. Work stopped early on Saturday (3:15 pm), with no work on Sunday.

In 1995 Historical Scotland (now Historical Environment Scotland) purchased Stanley Mills. In 1997 a private developer converted two of the buildings on the property into residential units (apartments). One other building has been turned into a museum.

Now its time for something to drink…

There’s a winery not too far away which allows motorhomes to stay overnight, a very good idea if you are going to be sampling!

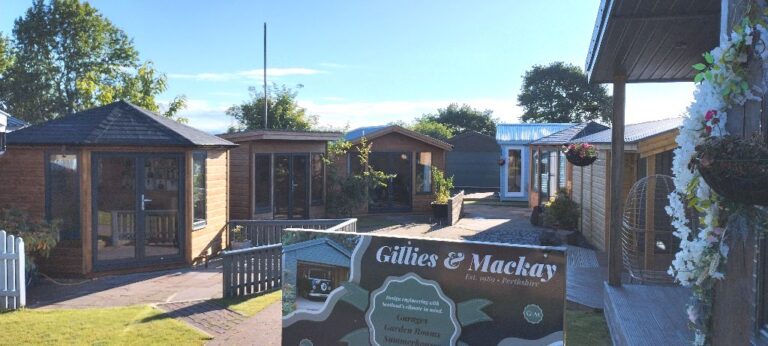

Cairn o’ Mohr (pronounced “care no more”) is part of a multi-generational farm and business. There are now three businesses on the property: the original and ongoing farm, the winery, and a shed making business.

The winery, the object of our closest scrutiny, for obvious reasons, is quite quirky. The largest quirk is that all of the products are made from fruit. With great trepidation we tasted concoctions that were derived from a variety of organic material such as: oak leaves, gorse flowers, elderberry, brambles, strawberries, cherries, honeyberries and apples.

Having nothing but bad experiences with fruit wines in the past, I held out hope for the apple cider and nothing else. I was most happily proved wrong. The fruit wines we sampled were very palatable, and the cider was excellent! We stayed for a second night, so that we could have a tour of the winery and dinner in the cafe. Our tour guide had worked at the winery for several years and had an encyclopedic knowledge that she shared willingly and rapidly. Between the speed of delivery of information, and the strange, almost incomprehensible dialect it was delivered in (English in theory, but we are in Scotland) we occasionally found ourselves at a loss, but this was remedied during the sampling session were questions could be asked, and answered, at a more leisurely pace.